How Carnegie Mellon University Is Using Robots to Break Down Your Old TV

The AI robots at roboLoop can disassemble TVs for recycling in 5 minutes — much quicker than a human can.

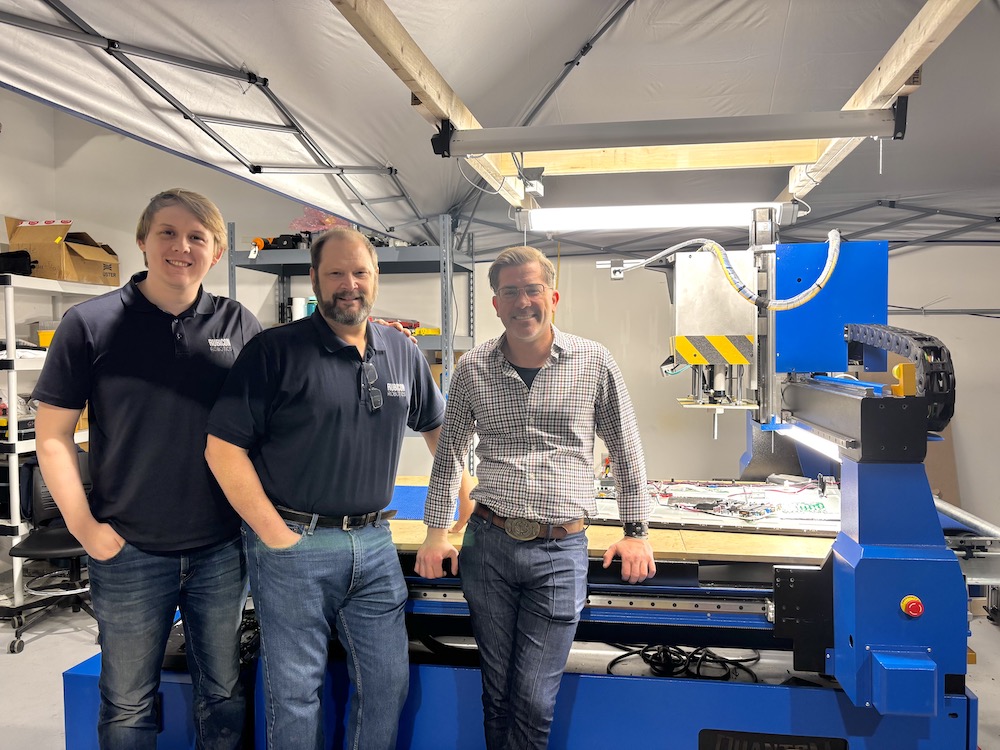

FROM LEFT: JORDAN FORD, JEFF FORD AND MATT TRAVERS, THE CARNEGIE MELLON UNIVERSITY TEAM THAT DEVELOPED THE PL-2 ROBOT BEHIND THEM THAT CAN DISSEMBLE A FLAT-SCREEN TV IN 5 MINUTES. | PHOTO BY TIANA EICHER

The increase in electronic waste is becoming a growing problem as technology develops and consumers continue to buy the newest products. When old products are discarded, they either go to a landfill or an e-waste recycling facility. Either way, they pile up faster than we can figure out what to do with them.

Recycling flat-screen TVs has been a particular challenge.

It takes a person about 15 minutes to disassemble one flat-screen television with power tools, which is labor-intensive and inefficient. But now a group of engineers at Carnegie Mellon University has created robots that can now break down TVs in 5 minutes or less.

Development of the project goes back five or six years when Apple approached CMU with the idea of adding artificial intelligence into electronics recycling.

CMU was working on the project for a while and “the technology itself was starting to get really mature,” says Matt Travers, a senior systems scientist in the CMU School of Computer Science’s Robotics Institute. So, they started reaching out to e-waste companies to find a home for their robots.

During their search through the Pennsylvania Recycling Markets Center, they learned about eLoop, a company based in Export in Westmoreland County.

“We were the very first recycler in the industry to use a robot,” says Ned Eldridge, founder and CEO of eLoop and roboLoop. Their first robot, manufactured in Ireland, arrived in April 2023. They gained national attention from this, which led to their partnership with CMU and eventual branching off of eLoop to create roboLoop.

CMU and roboLoop have been working together since fall of 2023. Now, the roboLoop facility in State College, Centre County, has two robots manufactured by the team at CMU. They received the first prototype, PL-1, earlier this year, and the second version, PL-2, was delivered on April 2.

For businesses to recycle and resell television parts, they must be fractionated, meaning all the components must be sorted into piles: circuit boards, plastics, copper and other materials.

Up until now, there have been two ways to break down a flat-screen TV: put it through a shredder and sort it with large-scale equipment or have people disassemble it with screw guns, pulling out all the pieces by hand and sorting them into different bins.

With the robot, CMU and roboLoop hope to increase the amount of televisions deconstructed from 400,000 pounds to 2 million pounds a month.

The robot unscrews the plastic off of the back of the television and then all circuit boards inside. It currently requires human aid to assist in quality control of finding the screws, but the team hopes this information can be stored in the computer so it eventually can locate the screws itself.

“What comes out of this robot is basically circuit boards, pieces of aluminum and pieces of plastic,” Travers says. “Prices for these commodities change all the time.”

Because of this, it is hard to make a profit off of manual labor. So, the addition of the robot will only help the e-waste industry grow, he says.

While the robot will be taking on the labor, he emphasized that roboLoop is not going to cause any loss of employment — it’s just a rearrangement of tasks.

The facility currently has 15 employees, eight of which work on the line disassembling the televisions. With the robots, they will need only four workers on the line to assist the robots and the other workers will do developmental tasks to continue growing the company.

RoboLoop also is creating a system of rotating shifts to avoid employee exhaustion, including swing shifts allowing the robot to run for 12 hours a day and increase efficiency.

“Under 5 minutes is the sweet spot, realistically where we would like to be is around 2 minutes,” Travers says.

TVs also create a plastic problem. Plastic is the fastest growing wastestream on Earth right now and nobody knows what to do with it, so the CMU team is working to come up with new ways to recycle the plastics from the televisions.

One idea is the addition of a system that can read the type of plastic on the back of a television, allowing for an easier sorting process to recycle the plastics. Eldridge says that another engineer in State College is aiding them in the addition of this sensor on the PL-2.

“This is revolutionary in our industry, no one’s doing that,” Eldridge says. “If we are able to create shredded plastic with no contamination, it is going to be worth more in the plastics industry.”

The facility in State College is within 300 miles of 20% of the U.S. population, where there is an average of two to three televisions per person, making it a prime location for e-waste.

Travers’ goal is to begin selling the robots to other facilities as well to improve the efficiency of the e-waste industry.